N-Methylpyrollidone (NMP) serves an important function as a powerful solvent in numerous applications including those in microelectronics, agriculture, pharmaceuticals, and industrial cleaning. Though NMP’s performance is proven in these industries, safe handling and worker exposure is of growing concern given NMP’s toxicological hazards. NMP is a confirmed reproductive toxin which has already led to strict restrictions on its use and labeling in both the US and the EU.

Dimethyl Sulfoxide (DMSO) and NMP are nearly alike in terms performance and physical properties; both are water miscible, highly polar solvents with high flashpoints, low vapor pressures, and comparable solvent parameters. Where DMSO differs from NMP is in its safety profile; DMSO is non-toxic by all routes of exposure, biodegradable, and safe. This combination of safety and performance makes DMSO the ideal candidate for NMP replacement.

Applications in which NMP is used Include:

- Microelectronics – Photoresist Film Removal

- Agrichemical Formulation

- Pharmaceutical

- Paints and coating

- Paint Strippers

- Metal Cleaning

- Polymer Production

- Solvent Extraction

- Aromatic Extraction

The data below serves to highlight key points of comparison between NMP and DMSO.

Is DMSO safer to use than NMP?

Yes. DMSO is considerably safer to use than NMP, as shown in table two. Regardless of exposure type, DMSO has favorable safety data to support its use.

The main worry associated with NMP is its reproductive toxicity. This issue is driving regulatory action in both the EU and the US, and is restricting its use in some applications.

In the US, the EPA recently evaluated NMP under the amended Toxic Substances Control Act (TSCA) and concluded the Final Risk Evaluation (December 2020). The results of the final risk evaluation determined that NMP exposes workers and consumers to unreasonable risks in 26 out of 37 conditions of use. These conditions include an array of use cases from cleaning applications to pharmaceutical and agrichemical applications. The EPA is in the process of determining risk management actions that may result in use restrictions.

| Toxicological Indicator | DMSO | NMP |

|---|---|---|

| Oral LD50 | 14,500 - 28,300 mg/kg rat | 3,914 mg/kg rat |

| Dermal LD50 | 40,000 mg/kg rat | 8,000 mg/kg rat |

| Inhalation (rat) | none @ 2,900 mg/m3 | N/A |

| Reproductive Toxin | No | Yes |

| Proposition 65? | No | Yes |

| ICH Residual Solvent Class | 3 | 2 |

Skin Penetration

There is some concern that solvents like DMSO and NMP can penetrate skin. In fact, both solvents do penetrate skin to approximately the same degree (figure 1). The use of appropriate gloves is always a good idea when handling solvents. For DMSO, Ansell TNT® Blue disposable nitrile gloves (VWR catalog # 32889-888) are recommended.

Although it has many solvent properties that resemble NMP, DMSO is safer to work with (oral, dermal, inhalation exposure).

| Solvent | Permeability Constant (g/m2h) |

|---|---|

| DMSO | |

| NMP | |

| DMAc | |

| MEK | |

| Methylene Chloride | |

| Water |

Will DMSO work as a substitute for NMP?

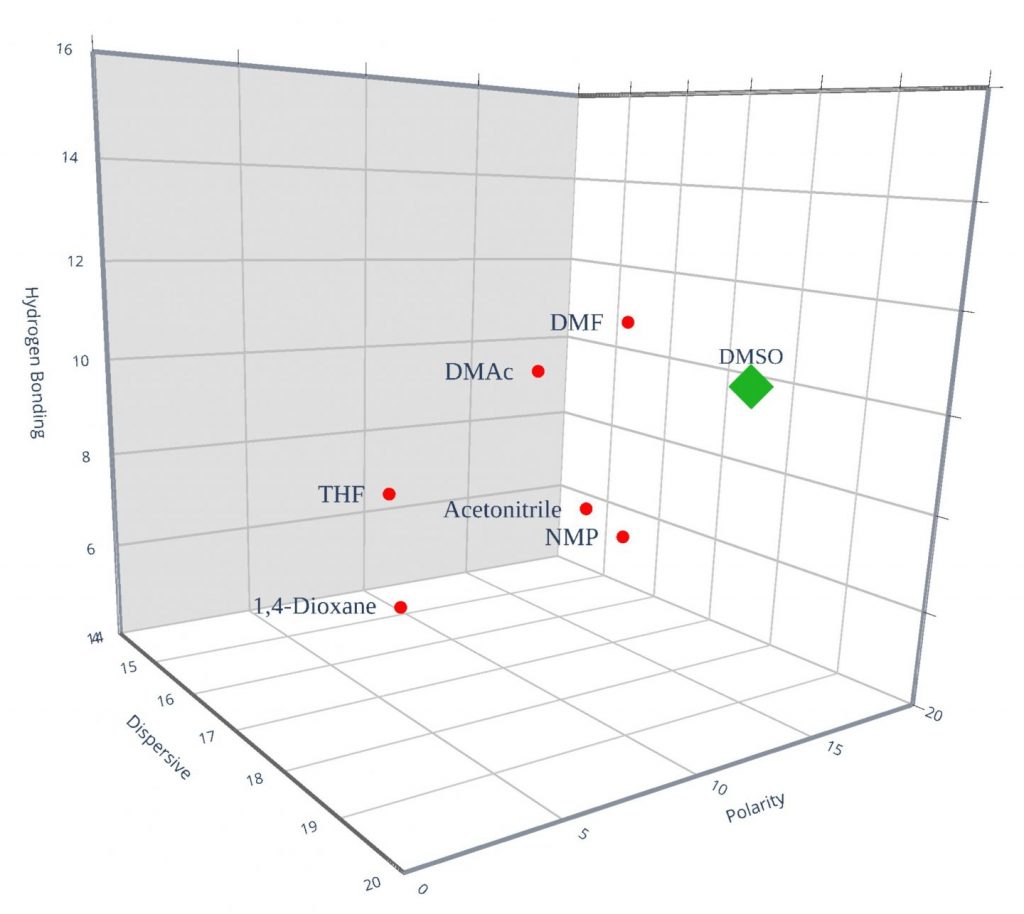

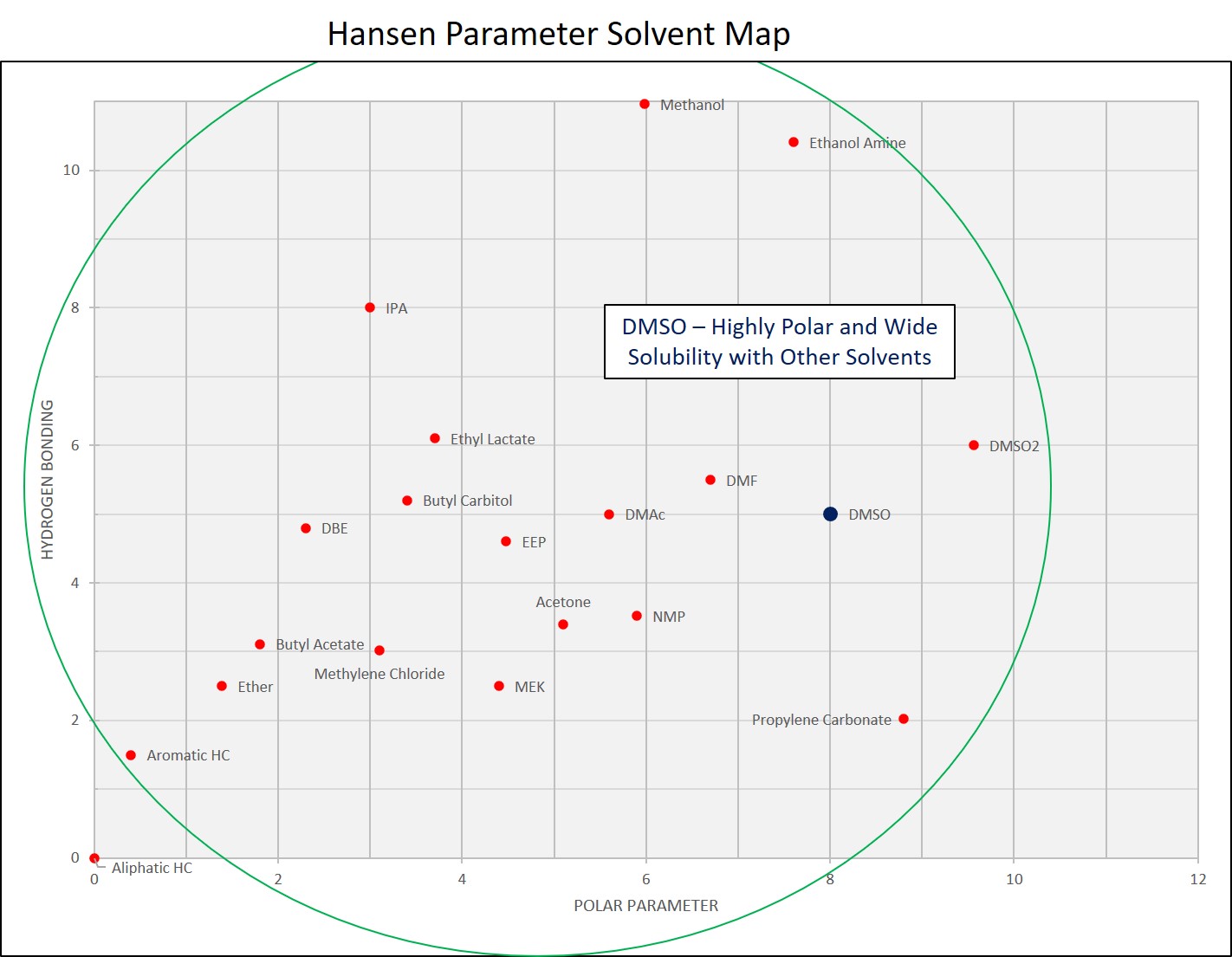

Both solvents are very polar materials, with high boiling points and low vapor pressures. DMSO has a smaller molar volume. Both are totally water soluble.

Although it is difficult to predict exactly how solvents will perform when one is directly substituted for another in an application, in most cases DMSO and NMP will work very similarly. Formulation with suitable cosolvents / additives can often make up for any differences in cleaning performance.

How Do their physical properties compare?

The basic physical properties of DMSO and NMP are nearly alike. Both have high flashpoints, low vapor pressures, and have comparable solvent parameters.

One difference worth noting is the relatively high freezing point of DMSO (18.5°C). When necessary, DMSO can be formulated to depress the mixture freezing point. Suitable drum-warming equipment is also readily available.

| Property | NMP | DMSO |

|---|---|---|

| CAS Number | [872-50-4] | [67-68-4] |

| Formula | C5H9NO | C2H6SO |

| MW | 99.13 | 78.13 |

| Solvent Class | Dipolar Aprotic | Dipolar Aprotic |

| mp, °C | -24 | 18.55 |

| bp, °C | 202 | 189 |

| Vapor Pressure @ 25°C (mm Hg) | 0.3 | 0.600 |

| Evaporation Rate (BuOAc=1) | 0.03 | 0.026 |

| Specific Gravity, 25°C/25°C | 1.033 | 1.0955 g/cm |

| Viscosity, cP @ 25°C | 1.67 | 2.0 |

| Flash Point. °C (Closed Cup) | 86 | 89 |

| Water Solubility, g/100g H2O at 25°C | 100 | 100 |

| Henry's Law Constant, (atm-m3/mole) | 1.56E-08 | 991000 21°C |

| Surface Tension (dynes/cm) @ 20°C | 40 | 43.53 |

| log Kow | -0.54 | -1.35 |

| Hildebrand Parameter (cal/cm3) | 11.3 | 13.0 |

| Autoignition Temp (air) | 270°C | 300-302°C |

| Specific Heat | 0.465 cal/g°C @ 50°C | 0.47 cal/g°C @ 29.5°C |

| Heat of Combustion (cal/g) | 7290 | 6054 |

How does regulatory treatment differ for DMSO and NMP?

In the US, products containing NMP must be labeled in the State of California as a developmental toxin under Proposition 65. DMSO is not “Prop 65” listed. There are reporting requirements for NMP in Massachusetts and Pennsylvania, which don’t exist for DMSO.

NMP has SARA §313 reporting requirements with a reporting threshold of 1%, while DMSO does not have this requirement.

Technical Service and Consultation

Gaylord Chemical provides application specific technical service in support of all of our product grades. From formulation development and regulatory consultation to Engineering and Design consultation, we’re here to help.